Air Receiver Tanks

With Our Manufacturing Experience

Leading Manufacturer and Exporter of Vertical Air Receiver Tanks, Horizontal Air Receiver Tanks, Chemical/Nitrogen Storage Tanks, Vacuum Tanks in Ahmedabad, Gujarat.

Over 5,000 sqm Factory Space

Ensuring Efficient Production Scale.

20+ Years Of Industry Experience

Delivering Proven Expertise.

Highest Customer Satisfaction

Proof of Our Quality Commitment.

Manufacturer and Exporter of Air Receiver Tank & Storage Tank

Veer Engineering India LLP is an ISO 9001:2015 certified organization and a leading manufacturers & supplier of Air Receiver Tanks and Storage Tanks in Ahmedabad, Gujarat, India. We have a comprehensive product range including Vertical Air Receiver Tanks, Horizontal Air Receiver Tanks, Chemical/Nitrogen Storage Tanks and Vacuum Tanks. The offered products are appreciated for being long lasting, perfect in terms of surface finish.

QUALITY

We served quality product to customers since 2004. We have proven our commitment to deliver quality products to clients.

TEAM

Our skillful and hard-working team of engineers help us to flawlessly meet the requirements of our customers.

DELIVERY

Delivering products on time is not always easy, but if done properly, it can help a business stand out from the competition.

CLIENTS

We believe in serving the best quality products to our clients. Veer Engineering India LLP prioritize providing products to customers.

ABOUT US

Veer Engineering India LLP involve in manufacturing and exporting wide range of air receiver tanks and storage tanks.

AFTER SALES SERVICE

We have very helpful service team available 24 x 7 days for our valued customer.

- 20+ Years of Manufacturing Experience

- Consistence Performance Over The Long Term

- Specialist in Air Receiver Tanks

- A 100% Quality Product Delivered

- High Customer Satisfaction

- 24x7 Amazing After Sales Service Approach

OUR

PRODUCTS

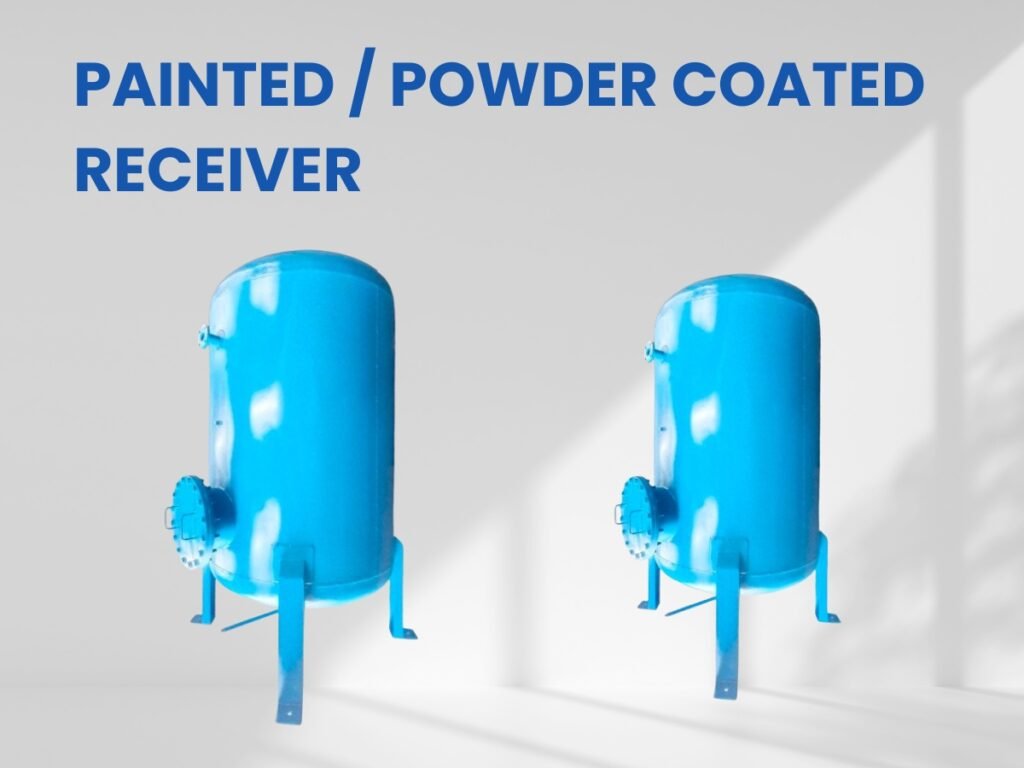

PAINTED / POWDER COATED RECEIVER

Painted/Powder Coated Receivers are used in the majority of cases where the air receiver is not submitted to extreme weather conditions and perfectly clean air is not an absolute prerequisite. The paint job ensures protection against corrosion.

Internal Paint: – Anti Rust Black Bituminous &

External Paint: – Epoxy Primer & Paint / Powder Coating

GALVANIZED RECEIVER

Galvanization is used to protect steel against corrosion. The process itself is simple: the vessel is completely submerged in a zinc liquid bath. As a result, the zinc coating perfectly adheres to the entire surface of the tank, ensuring full protection of the steel.

“HDGI” is provided on both Internal & External Surfaces.

FRP COATING RECEIVER

These Receiver are treated with Fiber Reinforced Plastic (FRP), also known as glass reinforced plastic (GRP), is specified to be coated, the appropriate coatings must be selected and the surface properly prepared, to assure long-term performance. FRP is resistant to chemicals, weatherproof, non-corrosive, impact resistant, fire retardant & Leak Proof.

“FRP” is provided on both Internal & External Surfaces.

SS BUFFING RECEIVER

SS Receivers mostly used in Chemical & Nitrogen storage purpose. Polishing improves the metal’s surface quality, helping keep stainless steel looking lustrous and, when combined with buffing, it leads to mirror-like finishes. Reduces corrosion: Polishing helps reduce the number and size of crevices in metal that encourage rust.

GET A QUOTATION

Products Gallery

ABOUT US

VEER ENGINEERING INDIA LLP founded in 2004 is an ISO 9001:2015, ISO 16528-1:2007 & CE-PED 2014/68/EU Certified organization and is engaged in Designing, Premier Manufacturing, Supplying & Exporter of Air Receiver Tank and All Types of Vessels.

Scan For Brochure

OUR PRODUCTS

SOCIAL LINKS

CONTACT US

Address

Phone No